Copper is one of the most widely used metals in precision manufacturing. Its exceptional electrical and thermal conductivity, corrosion resistance, and machinability make it indispensable in industries such as electronics, aerospace, automotive, and energy.

However, to fully harness copper’s potential in CNC machining, understanding one of its fundamental physical properties—density—is essential.

The density of copper not only affects how it behaves during machining but also determines critical factors like tool wear, feed rate, cutting force, and final part performance. This article explores the relationship between copper’s density and CNC machining, helping engineers make better material and process decisions.

1. What Is the Density of Copper?

Copper has a density of approximately 8.96 g/cm³ (8960 kg/m³) at room temperature. This makes it significantly denser than aluminum (2.7 g/cm³) but lighter than many heavy alloys such as tungsten or lead.

This high density means copper has a tight atomic structure, which contributes to its:

- Excellent electrical conductivity (second only to silver)

- High thermal conductivity, allowing efficient heat transfer

- Outstanding corrosion resistance

- Good strength and wear resistance

In CNC machining, these characteristics make copper ideal for parts that must endure mechanical stress while maintaining electrical or thermal performance.

2. How Copper Density Affects CNC Machining

The density of copper has direct implications for how it behaves under machining conditions. Its mass, hardness, and heat transfer capacity all influence tool choice, cutting parameters, and machining outcomes.

(1) Cutting Force and Tool Load

Copper’s high density translates to greater resistance against cutting. When the tool engages the material, cutting forces and torque requirements increase compared to lightweight metals such as aluminum.

To compensate, machinists often:

- Use sharper cutting tools with fine edges to reduce friction.

- Optimize feed rates and spindle speeds to maintain stable cutting without excessive heat buildup.

- Apply rigid machine setups to prevent vibration and ensure precision.

(2) Heat Generation and Dissipation

Copper’s density also correlates with its exceptional thermal conductivity, which helps dissipate heat quickly during machining. This reduces the risk of localized thermal deformation but can also transfer heat rapidly to cutting tools, accelerating tool wear if cooling is inadequate.

To control temperature, coolants or lubricants are essential. Water-based coolants and mist systems are commonly used to maintain consistent cutting performance and prolong tool life.

(3) Surface Finish Quality

The heavy, ductile nature of copper can make it prone to smearing or burring if cutting tools are dull or parameters are incorrect. Achieving a fine surface finish requires:

- Precision-ground carbide or diamond tools.

- Proper chip evacuation through high-pressure coolant flow.

- Fine-tuned feed and depth of cut settings.

Well-machined copper parts can achieve mirror-like finishes that are ideal for electrical contacts, heat exchangers, and precision connectors.

3. Copper Alloys and Their Machinability

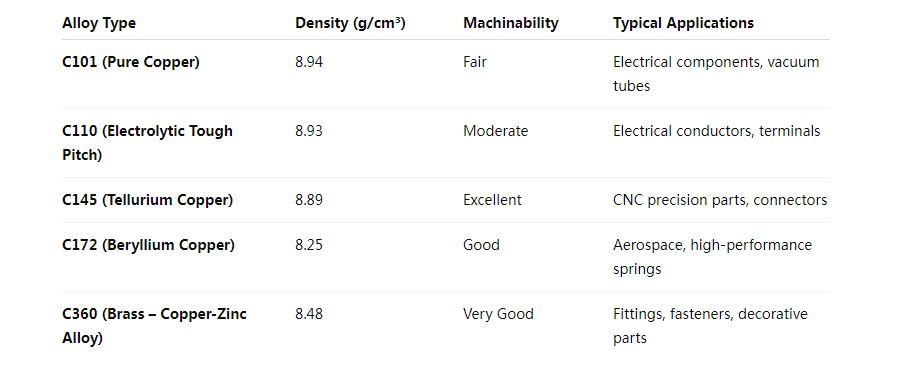

Pure copper, while offering superior conductivity, is relatively soft and sticky, which can make machining more challenging. As a result, many industries use copper alloys to balance density, strength, and machinability.

Tellurium copper (C145) and beryllium copper (C172) are especially popular for CNC machining due to their improved chip formation and dimensional stability, while maintaining good conductivity and strength.

4. CNC Machining Techniques for High-Density Copper

Because of copper’s density and thermal characteristics, optimizing machining parameters is crucial for quality and efficiency.

Tool Selection

Carbide tools are preferred for high-speed machining due to their hardness and resistance to wear.

For ultra-fine surfaces or micro-features, polycrystalline diamond (PCD) or CBN tools provide superior edge retention.

Cutting Parameters

Moderate cutting speeds (100–300 m/min) help balance tool life and surface quality.

Low feed rates and shallow depth of cut reduce vibration and tool load.

High-pressure coolant delivery ensures effective chip removal and temperature control.

Fixturing and Stability

Copper’s density means heavier parts may require robust fixturing systems to prevent micro-movement. Vacuum fixtures or soft jaws lined with non-marring materials can protect delicate surfaces while maintaining rigidity.

5. Why Density Matters Beyond Machining

Beyond machining performance, copper’s density also affects:

- Component weight – influencing the overall mass of assemblies in aerospace or electronics.

- Thermal management – dense copper parts are ideal for heat sinks, electrodes, and conductive bases.

- Dimensional stability – high density minimizes vibration during operation, which enhances performance and longevity.

In industries where precision, conductivity, and thermal control are essential, these properties make copper an irreplaceable material.

6. Alternative Materials to Consider

While copper is excellent for performance-critical applications, other materials can offer similar advantages with different trade-offs:

- Brass – slightly less dense, easier to machine, still conductive.

- Aluminum – lightweight, less costly, but lower strength and conductivity.

- Stainless Steel – stronger and corrosion-resistant, though less conductive.

The right choice depends on whether electrical conductivity, structural integrity, or cost efficiency is the priority.

7. Conclusion

The density of copper plays a pivotal role in how it behaves during CNC machining and how it performs in its final application. Its high density contributes to excellent conductivity, strength, and durability—but also demands precise machining parameters, advanced tooling, and effective cooling control.

Understanding copper’s physical characteristics allows engineers and machinists to achieve the best balance between performance, cost, and manufacturability. When handled correctly, copper remains one of the most valuable and versatile materials for CNC machining, powering innovations from microelectronics to heavy industrial equipment.