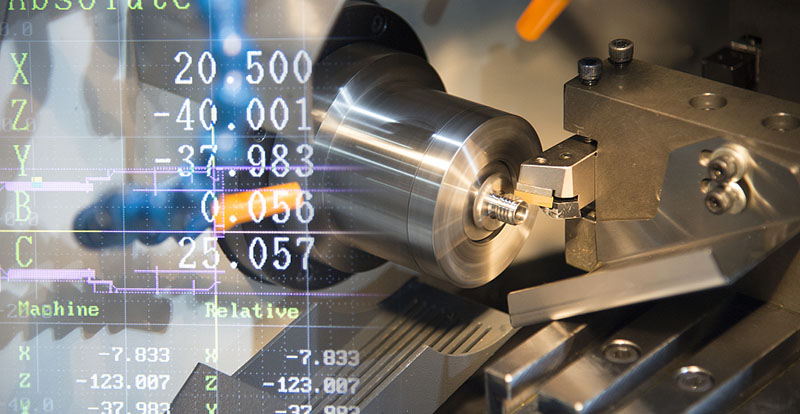

Across the vast manufacturing sector, CNC machining has long been a mainstay for ensuring precision and efficiency. However, with the surge of technological advancement, artificial intelligence (AI) is sweeping across CNC machining at an unprecedented pace, revolutionizing CNC machining and ushering in a new era of intelligent manufacturing.

Improving Precision and Quality Control

In CNC machining, precision is paramount. In the past, even if CNC equipment could follow programmed instructions, variations in machining accuracy were inevitable due to numerous factors, such as tool wear and fluctuations in material properties. The introduction of artificial intelligence (AI) has given CNC machining the “smart eyes” and “super brain.”

By collecting and analyzing data from CNC equipment sensors in real time, AI algorithms can keenly detect even the slightest deviations and anomalies. Once it detects that the machining process has deviated from the preset accuracy range, the AI system rapidly calculates and issues precise adjustment instructions to ensure continued high-precision machining. A 2023 Deloitte report indicates that AI-driven quality control systems can reduce CNC machining defect rates by up to 50%. This means significantly improved product consistency and reduced rework, enabling companies to earn market and customer trust with higher-quality products.

Predictive Maintenance Reduces Costs

Unplanned downtime caused by equipment failures is a nightmare for production schedules and cost control. Traditional CNC equipment maintenance relies on scheduled inspections or reactive repairs after a failure occurs, which is resource-intensive and difficult to prevent unexpected failures. AI-powered predictive maintenance is the key to solving this problem.

AI systems deeply analyze historical equipment performance data and real-time operating status data, using machine learning models to build predictive models of equipment health. These models accurately estimate the remaining service life of key equipment components, proactively identify potential failures, and alert maintenance personnel. According to McKinsey research, companies can reduce maintenance costs by up to 25% and reduce unplanned downtime by up to 30-40% by adopting AI-driven predictive maintenance strategies. This not only ensures production continuity but also makes companies’ investments in equipment maintenance more proactive and scientific, effectively reducing operating costs.

Optimizing Tool Paths to Improve Efficiency

Tool path planning directly impacts CNC machining efficiency and material utilization. Traditional tool path planning relies heavily on manual experience or relatively fixed algorithms, making it difficult to achieve optimal solutions in complex machining scenarios. AI algorithms demonstrate significant advantages, enabling in-depth mining and analysis of massive amounts of historical machining data to simulate the effects of different tool paths under various machining conditions.

Based on the simulation results, the AI system automatically generates and continuously optimizes the tool path, finding the optimal solution with the shortest machining time, minimal tool wear, and minimal material waste. A 2024 study in the International Journal of Production Economics showed that AI-driven scheduling systems can increase production efficiency by as much as 20%. Optimized tool paths enable smoother equipment operation and significantly shorten machining cycles, enabling companies to produce more products per unit time and enhance their market competitiveness.

Achieving Advanced Process Automation

Artificial intelligence empowers CNC machining with a new level of automation, effectively facilitating everything from tedious equipment operation procedures to complex production task switching. During the machine startup phase, the AI system automatically completes a series of preparatory tasks, including machine parameter setting, tool selection, and installation, based on the part information being processed, significantly reducing machine commissioning time.

During machining, if a worn tool requires replacement or the machining task requires a temporary change, the AI system autonomously coordinates the movements of various machine components, enabling rapid tool changes and seamless switching of machining strategies, without requiring significant human intervention. According to a Deloitte survey, nearly 70% of manufacturers adopting intelligent technologies have deployed or plan to deploy AI-driven automation systems to improve operational efficiency. Increased automation not only speeds up production but also significantly reduces human error, resulting in a more stable and efficient production process.

Enhancing Customization and Flexibility

Currently, market demand for personalized product customization is increasing, posing a significant challenge to the flexibility of CNC machining. Artificial intelligence injects powerful flexibility into CNC machining, helping companies easily adapt to the increasing demand for customization. AI systems can rapidly analyze complex custom design drawings and instantly generate customized machining plans based on the part’s unique geometry, dimensional requirements, and material properties.

Facing the demands of small-batch, high-variety production, AI-driven CNC equipment can rapidly adjust machining parameters and toolpaths, flexibly switching between different product lines. This switching process is efficient and precise, without compromising machining efficiency and quality due to frequent adjustments. This high level of flexibility enables companies to quickly respond to market changes, meet diverse customer customization needs, and expand into a broader market.

AI-Programmed CNC Machines

Traditional CNC machine programming is often complex and time-consuming, requiring professional programmers to manually write extensive code based on machining drawings. Even the slightest oversight can lead to errors. The integration of AI technology revolutionizes this traditional programming model. AI systems intelligently analyze 3D models, gaining a deep understanding of key information such as part geometry and dimensional tolerances. Subsequently, by simulating different toolpaths and machining strategies, and incorporating factors such as material properties and machine performance, they automatically generate efficient and accurate control codes (G-code and M-code). This process significantly shortens programming time, reduces programming difficulty, and minimizes human programming errors, making CNC machining programming more efficient and intelligent.

In summary, the deep integration of AI and CNC machining is reshaping the manufacturing landscape in all aspects. From improving precision and quality, to reducing costs and increasing efficiency, to enhancing flexibility and customization, the transformation brought about by AI to CNC machining is revolutionary. For manufacturing companies, actively embracing AI technology and implementing AI-driven CNC solutions is key to standing out in the fierce market competition and achieving sustainable development. With the continuous iteration and innovation of AI technology, CNC machining will surely reach new heights of greater intelligence, efficiency, and precision, injecting a continuous and powerful impetus into the development of the manufacturing industry.