In modern precision manufacturing, CNC milling technology is central to achieving efficient, high-precision machining of complex parts. Within this process, cutting speed (Vc) is the “soul” of all machining parameters. It’s not only a key variable determining machining efficiency but also the “master switch” affecting tool life, workpiece surface quality, and machining costs. Correctly understanding and optimizing cutting speed is a balancing act that every CNC engineer and technician must master.

What is Cutting Speed? (And Why It’s Not RPM)

First, we must correct a common misconception. Cutting Speed is not the same as Spindle Speed (RPM).

Spindle Speed (RPM): Revolutions Per Minute simply measures how fast the machine’s spindle is rotating. It is a machine-centric parameter.

Cutting Speed (CS): This is the relative surface speed between the cutting edge of the tool and the workpiece. It is a process-centric parameter, describing the physics of the cut itself. It is measured in Surface Feet per Minute (SFM) in the imperial system or meters per minute (m/min) in metric.

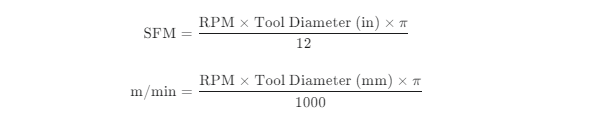

The relationship is defined by the tool’s diameter:

This distinction is critical. A 1/4″ end mill spinning at 10,000 RPM has a cutting speed of ~2,618 SFM. A 4″ face mill spinning at the same 10,000 RPM would have a theoretical cutting speed of ~10,472 SFM—a completely different world of interaction between the tool and the material. Therefore, Cutting Speed is the universal language for defining a process, independent of tool size.

The central importance of cutting speed

Driving Efficiency: Material Removal Rate (MRR)

In a production environment, time is money. Material Removal Rate (MRR)—the volume of material removed per minute—is a key performance indicator. Cutting speed is a direct multiplier in the MRR formula.

MRR (in³/min)=Radial Depth of Cut (in)×Axial Depth of Cut (in)×Feed Rate (in/min)

Since feed rate is derived from cutting speed, a higher cutting speed allows for a higher feed rate, thus increasing MRR. However, this creates the central economic trade-off in machining: Speed vs. Tool Life. Pushing for the absolute maximum MRR will drastically reduce tool life and increase tooling costs. The goal is to find the economic balance point where the time saved in the cut outweighs the cost of more frequent tool changes.

Eg: When machining 6061-T6 aluminum alloy, increasing the cutting speed from 600 m/min to 1200 m/min can theoretically cut machining time in half, significantly increasing productivity.

The Decisive Impact on Tool Life

Cutting speed is arguably the single most significant factor affecting how long a tool lasts. The underlying principle is heat generation and management. The energy used to shear a chip is primarily converted into heat at the cutting zone.

Too Slow: Running a tool below its recommended cutting speed might seem like a safe bet, but it often leads to Built-Up Edge (BUE). This occurs when workpiece material welds itself to the cutting edge due to excessive pressure and friction at low temperatures. BUE ruins the tool’s geometry, increases cutting forces, and ultimately causes the edge to chip when the BUE violently breaks away. This is especially common in gummy materials like aluminum and some stainless steels.

Too Fast: Exceeding the recommended cutting speed generates heat faster than the tool’s substrate and coating can withstand. This leads to rapid thermal-based wear mechanisms such as:

- Plastic Deformation: The cutting edge gets so hot that it softens and deforms under pressure.

- Crater Wear: The top of the insert erodes as super-heated chips flow over its surface.

- Rapid Oxidation: The coating breaks down, exposing the carbide substrate to failure.

Finding the optimal cutting speed puts you in a “sweet spot” where the material is sheared cleanly and the majority of the heat is effectively evacuated in the chip, protecting both the tool and the workpiece.

The Key to a Superior Surface Finish

The surface finish of a milled part is a direct reflection of the cutting action’s quality and stability. Cutting speed plays a pivotal role here.

By operating within the optimal range, you promote a clean shearing action rather than a “plowing” or tearing of the material. Increasing the cutting speed (from a too-slow state) is often the first step to resolving a poor surface finish because it helps eliminate the previously mentioned BUE, which is a primary cause of rough, inconsistent surfaces. A clean, sharp cutting edge moving at the correct velocity leaves behind a smoother, more uniform finish.

Machining Costs Affection

Choosing cutting speed is a comprehensive economic decision. While increasing cutting speed can reduce labor costs per piece, it also increases tool consumption and machine depreciation. By calculating the total cost per part, we can find the “economical cutting speed” that minimizes total cost.

Eg.: In large-scale production, using high-performance coated tools (such as TiAlN), even though they are more expensive, can significantly reduce total cost per part because they can withstand higher cutting speeds.

Guide To Optimizing Cutting Speeds

Material-Specific Considerations

There is no “one-size-fits-all” cutting speed. The optimal value is fundamentally dictated by the material being machined.

- Aluminum Alloys:Generally machined at very high cutting speeds. This is necessary to avoid BUE and leverage the material’s excellent machinability.

- Carbon & Alloy Steels: Machined at moderate speeds. The correct speed is a careful balance to manage heat and prevent rapid tool wear.

- Titanium & High-Temp Alloys (Inconel):Machined at very low cutting speeds. These materials are poor thermal conductors. They do not evacuate heat in the chip effectively, instead concentrating it directly into the tool. Exceeding the low recommended cutting speed will result in near-instantaneous tool failure.

Tool-focused optimization

Tool materials: High-speed steel (HSS) < Carbide < Ceramic < PCD. The higher the grade, the higher the cutting speed it can withstand.

Tool coatings: Coatings such as TiN, TiAlN, and AlTiN effectively insulate heat and protect the tool substrate, allowing cutting speeds to be increased by 20%-50%.

Geometry: Sharp rake angles and large chip pockets help reduce cutting forces, allowing stable machining at higher speeds.

Ensuring machine tools and systems

Machine rigidity: Highly rigid machine tools effectively suppress vibrations caused by high-speed cutting and are a prerequisite for achieving high-speed cutting.

Cooling and lubrication: High-pressure coolant not only removes heat but also effectively evacuates chips, preventing secondary cutting. Minimum quantity lubrication (MQL) is also an effective method for difficult-to-machine materials.

CAM strategies: Utilizing trochoidal milling or high-speed milling (HSM) strategies can maintain high cutting speeds while distributing the cutting load and protecting the tool.

Conclusion:

Cutting speed isn’t a simple number; it’s a “living parameter” that requires a constant and dynamic balance between efficiency, quality, and cost. A good CNC process engineer doesn’t blindly pursue the ultimate speed. Instead, they prioritize the material, tool, machine, and actual working conditions through theoretical calculations, empirical judgment, and small, quick trials to ultimately identify the optimal solution that best meets current production goals.

In the era of intelligent manufacturing, with the widespread adoption of adaptive control technology and sensor-based real-time optimization systems, cutting speed adjustment will become even more intelligent and precise. However, understanding its underlying logic and importance is always the first and most important step.