In modern manufacturing, surface treatments play a critical role in enhancing the performance, durability, and appearance of metal components. Among various coating techniques, black oxide coating stands out as a reliable and cost-effective method for improving corrosion resistance and surface aesthetics, especially for steel and ferrous metals. This article provides a comprehensive guide to black oxide coating—explaining its formation process, key advantages, and practical applications across industries.

What Is Black Oxide Coating?

Black oxide, also known as blackening or blackening finish, is a chemical conversion coating applied to ferrous metals. It converts the outer layer of the metal into magnetite (Fe₃O₄), a stable black iron oxide, through a controlled chemical reaction.

Unlike paint or plating, black oxide doesn’t add a separate layer on top of the material; instead, it becomes an integral part of the surface, offering distinct functional and visual advantages. This treatment increases wear and corrosion resistance while making components look better visually. So it’s become a popular procedure for many industrial operations.

Black Oxide Coating Process

Understanding how black oxide coating works is essential for achieving optimal results. Let’s break down the process step by step.

Surface Preparation

Proper surface preparation ensures high-quality coating and strong adhesion. The first step involves thoroughly cleaning the metal surface to remove dirt, oil, and oxides. This can be achieved through various methods such as sandblasting, chemical etching, or degreasing. For complex parts, a combination of alkaline cleaning and acid pickling is commonly used to obtain a clean and reactive surface.

Oxidation Tank

The oxidation tank is the core of the black oxide process. This heated alkaline solution typically operates at a temperature of 140°C to 146°C and contains oxidizing agents and sodium hydroxide. Parts are immersed for 10 to 30 minutes to promote the chemical reaction. As a result, a layer of magnetite (Fe₃O₄) forms on the metal surface, producing the characteristic black coating.

Post-Treatment

After oxidation, parts are thoroughly rinsed to remove any residual chemicals, followed by the application of a sealant. Common sealants include oil, lacquer, or wax. When the sealant penetrates the porous oxide layer, it enhances corrosion resistance and achieves the desired surface finish. Wax produces a matte finish, oil provides a glossy appearance, and lacquer offers quick drying with decorative appeal.

Key Process Variations

The black oxide process is not one-size-fits-all. Different materials and application requirements call for specific process adjustments. For example, aluminum requires a zinc immersion pre-treatment, while stainless steel uses specialized oxidation solutions. Some procedures use cold black oxide, which relies on chemical reactions at room temperature. Others involve electrolytic methods to enhance the oxidation effect. These variations ensure optimal coating performance across a wide range of materials and specifications.

Benefits of Black Oxide Coating

Black oxide coating gives a range of advantages across different industries. One outstanding feature is its ability to protect against corrosion.

Enhanced Corrosion Resistance

By itself, black oxide offers moderate corrosion resistance, but when combined with post-sealing (oil or wax), it significantly reduces oxidation, especially in indoor environments.

Improved Aesthetics

The deep black finish provides an attractive, non-reflective surface, enhancing the appearance of tools, fasteners, and machinery components.

Dimensional Stability

Unlike plating or painting, black oxide adds minimal thickness (typically 0.5 to 2.5 microns), preserving part dimensions and tolerances—crucial for precision components.

Reduced Light Glare

The matte black appearance minimizes glare, making black oxide popular in optical components, military equipment, and instrument housings.

Lubricity and Anti-Galling Properties

The oil or wax seal enhances surface lubricity, reducing friction and preventing galling or seizing of mating components.

Cost-Effective Surface Protection

Compared to more expensive coatings like plating or painting, black oxide offers a budget-friendly option with satisfactory protection and improved appearance.

Limitations and Challenges

While black oxide coating offers many advantages, it also comes with certain drawbacks. To ensure proper application, it is important to consider the following limitations:

Thickness Limitation

One of the main limitations of black oxide coating is its very thin layer, typically ranging from 0.5 to 1.5 microns. This minimal thickness results in reduced protection under extremely harsh environmental conditions and limits the ability to maintain precise dimensional accuracy. When a thicker protective layer is required, alternative surface treatments should be considered.

Durability Issues in Cold Processing

Cold black oxide processes offer faster application but generally have lower durability compared to hot black oxide treatments. To address this issue, manufacturers often prefer the hot black oxide process or choose high-quality sealants in applications where maximum durability is necessary.

Safety and Environmental Concerns

The use of corrosive chemicals in the hot black oxide process raises safety and environmental concerns. To mitigate these risks, industry professionals have developed modern chemical formulations and follow strict safety protocols to ensure environmentally responsible operations.

Heat Resistance Limitations

Although black oxide coatings can perform effectively at temperatures up to 900°F (approximately 474°C), they still have limitations in extreme high-temperature environments. Engineers should consider alternative coating options that are specifically designed for higher temperature resistance.

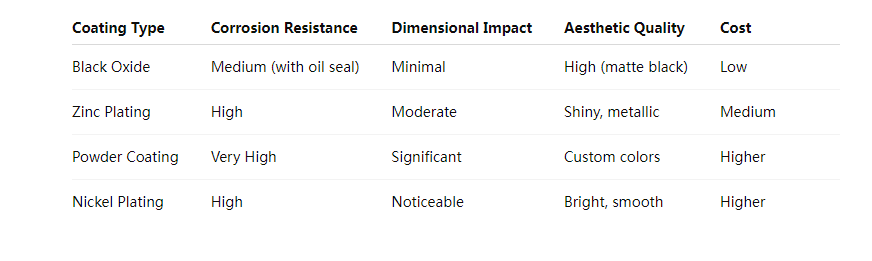

Black Oxide vs. Other Coating Methods

Conclusion

Black oxide coating remains a popular finishing option due to its low cost, dimensional accuracy, corrosion resistance, and sleek appearance. While it may not provide the robust protection of thick platings, it strikes an excellent balance for many industrial, commercial, and consumer applications.

If you require components with minimal dimensional change, reduced glare, and improved wear resistance, black oxide treatment offers a practical and effective solution.