Aluminum is one of the most widely used materials in CNC machining, valued for its excellent strength-to-weight ratio, corrosion resistance, and superb machinability. From aerospace structures to automotive components and consumer electronics, CNC machined aluminum parts are essential in modern manufacturing.

This comprehensive guide covers everything you need to know about aluminum CNC machining—material benefits, common grades, machining techniques, design considerations, and key industrial applications.

Why Choose Aluminum for CNC Machining?

Excellent Machinability

Aluminum is soft compared to other metals, which allows high-speed machining with less tool wear. It supports faster cycle times, lower energy consumption, and reduced machining costs.

High Strength-to-Weight Ratio

Aluminum alloys combine lightweight characteristics with impressive mechanical strength, making them ideal for structural components in industries where weight reduction is crucial.

Corrosion Resistance

Many aluminum grades naturally resist corrosion, eliminating the need for additional protective coatings in many applications, especially in marine and outdoor environments.

Aesthetic Versatility

Aluminum accepts various surface finishes—from anodizing to polishing—providing both functional and decorative options for end-use parts.

Good Thermal and Electrical Conductivity

Aluminum parts are common in heat sinks, electronic enclosures, and connectors due to their superior thermal and electrical performance.

Common Aluminum Grades for CNC Machining

Selecting the right aluminum alloy is crucial for optimizing performance and cost. Here are some popular choices:

6061 Aluminum

The most commonly used grade; offers balanced strength, corrosion resistance, and weldability. Suitable for general-purpose machining.

7075 Aluminum

High-strength alloy with excellent fatigue resistance, commonly used in aerospace and performance automotive components.

2024 Aluminum

Known for high fatigue resistance and strength, but lower corrosion resistance. Popular in aerospace structures.

5083 Aluminum

Exceptional corrosion resistance, especially in marine applications. Slightly more challenging to machine.

MIC-6 Aluminum (Cast Plate)

Flatness stability, low internal stress, and good dimensional accuracy make it ideal for precision components and tooling plates.

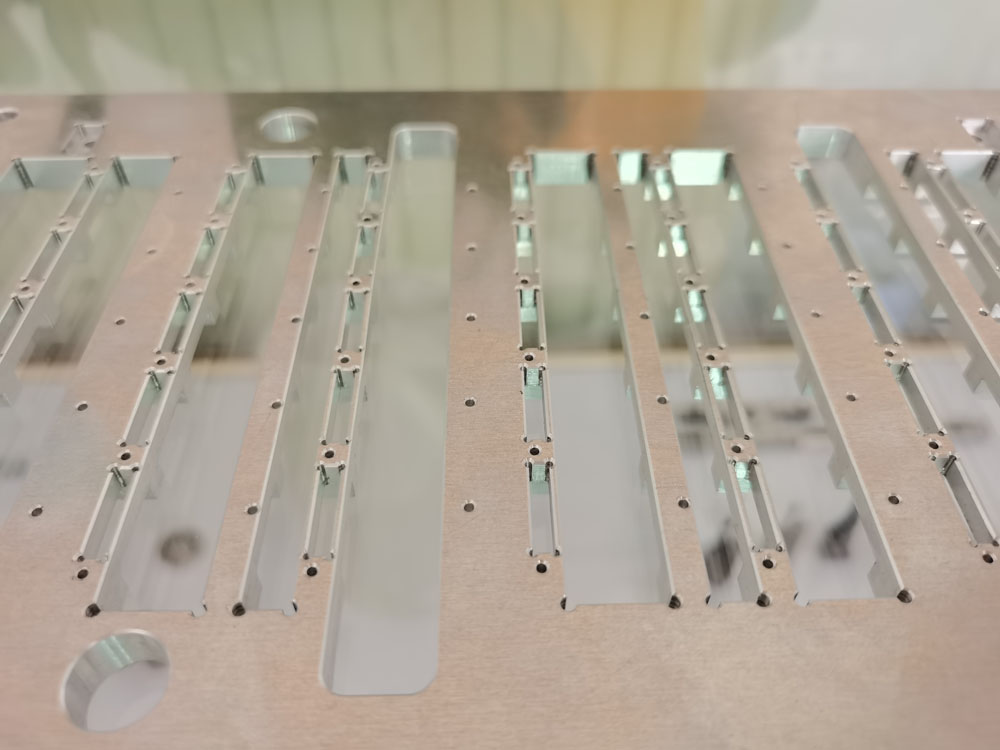

CNC Machining Processes for Aluminum Parts

CNC Milling

Used to produce flat surfaces, pockets, contours, and complex 3D shapes.

High-speed milling is feasible due to aluminum’s softness and low cutting resistance.

CNC Turning

Ideal for round parts like bushings, shafts, connectors, and flanges.

Achieves excellent surface finishes and tight tolerances in cylindrical components.

Drilling & Tapping

Aluminum drills cleanly with low wear on drill bits.

Tapping is easier compared to harder metals, producing durable internal threads.

Surface Finishing

Anodizing: Enhances corrosion resistance and appearance.

Bead Blasting: Creates uniform matte textures.

Powder Coating/Painting: Adds color and protection.

Polishing: Achieves mirror-like finishes for decorative parts.

Design Considerations for CNC Aluminum Parts

Wall Thickness: Minimum recommended wall thickness is 1.0 mm for rigidity.

Tolerances: Standard CNC machining can achieve ±0.05 mm; tighter tolerances are achievable upon request.

Fillets and Radii: Internal corners should have a radius to improve machining efficiency and tool life.

Threading: Coarser threads (UNC) perform better in softer materials like aluminum.

Heat Treatment: Some aluminum grades can be heat-treated to improve mechanical properties post-machining.

Applications Of CNC-Machined Aluminum Parts

Aerospace Components: CNC aluminum components dominate the aerospace sector. They are light and strong, suitable for aircraft fuselages, wings, and engines.

Automotive Parts: Aluminum is widely used to make engine blocks, transmission housings, and other structural components. It helps reduce weight and improves the overall performance and fuel economy of the vehicle.

Electronic Housings: Aluminum is the material of choice for electronic housings and other cooling components because its thermal and processing properties are the best.

Medical Devices: Aluminum is used in parts for surgical instruments and diagnostic equipment because it is lightweight, compatible with the human body, and strong and durable.

Robotics and Automation: Aluminum is widely used in gears, bearings, and arms for robotics and automation equipment that require precision because of its ease of manufacturing and light weight.

Benefits of CNC Machined Aluminum Parts

1. Outstanding Production Flexibility

Aluminum’s compatibility with CNC technology allows manufacturers to seamlessly shift from prototypes to large-scale production without expensive tooling changes. Whether producing a one-off custom component or a run of 100,000 units, CNC machining offers scalability unmatched by casting or molding.

2. Cost-Effective Manufacturing

Compared to many metals like stainless steel or titanium, aluminum requires shorter machining times, reduces tooling costs, and minimizes energy consumption during manufacturing. This translates directly into lower per-part costs, especially in medium to high production volumes.

3. High Dimensional Accuracy

CNC machining provides tight tolerances (commonly ±0.05 mm or tighter), essential for components requiring interchangeability, precision fit, and minimal post-processing. Machined aluminum parts can achieve exceptional flatness, parallelism, and concentricity with less effort.

4. Superior Surface Quality

Even in as-machined condition, aluminum offers a naturally smooth, reflective finish. Post-machining processes like bead blasting or anodizing further improve surface texture and durability, making aluminum ideal for visible consumer components and high-end equipment.

5. Quick Turnaround and Rapid Prototyping

Aluminum’s high machinability means faster cycle times and shorter lead times. This makes it especially beneficial in product development environments where speed-to-market is crucial, enabling iterative design improvements without long production delays.

6. Lightweight without Sacrificing Strength

In weight-sensitive industries such as aviation, drones, robotics, and performance vehicles, aluminum delivers the strength needed to ensure durability, while dramatically reducing overall system weight—enhancing fuel efficiency and operational performance.

7. Environmentally Friendly

Aluminum is highly recyclable without losing key material properties. Many CNC machining projects utilize recycled aluminum billets, supporting sustainability goals while maintaining quality, helping manufacturers reduce environmental impact.

8. Excellent Thermal and Electrical Properties

Machined aluminum parts can handle both thermal management (e.g., heat sinks) and electrical applications (e.g., connectors, housings), reducing the need for multiple materials within a single assembly—simplifying designs and reducing costs.

9. Compatible with Complex and Intricate Designs

With multi-axis CNC capabilities, aluminum can be machined into complex geometries, undercuts, thin walls, or fine details that are often impractical with other materials. This opens up opportunities for innovative product designs without significant cost increases.

CNC machined aluminum parts offer manufacturers an ideal balance between performance, cost, and versatility. With excellent machinability, lightweight properties, and aesthetic adaptability, aluminum continues to dominate industries ranging from aerospace to consumer electronics.

By understanding aluminum grades, design principles, and CNC processes, manufacturers can optimize production outcomes and unlock new possibilities in component performance and functionality.