Grinding and hard turning are two technologies that control critical dimensions, and each has advantages in terms of precision and efficiency. So which one should you choose?

Grinding Overview

Grinding is the cornerstone of precision machining and is known for its ability to achieve excellent surface finish and high precision, especially for difficult-to-machine materials. The process uses grinding wheels to quickly remove material, achieving unparalleled precision and surface texture. Its versatility covers a wide range of applications, from manufacturing complex components to finishing large, heavy parts with tight tolerances. While grinding is acclaimed for its ultra-fine surface finish and tight dimensional control, which is essential for industries such as aerospace and automotive, it does face limitations in terms of speed and cost-effectiveness. Despite these challenges, grinding’s high-precision machining capabilities still play a key role in modern manufacturing processes.

Grinding is a machining process that uses a grinding wheel as a cutting tool. It is commonly used in finishing applications to achieve high precision and high surface quality. The extremely precise grinding process can achieve form accuracy of 0.5-1 micron, dimensional accuracy of ≤1 micron, and surface roughness of 0.1 micron Ra. However, the notion that grinding is only for high-end workpieces is completely wrong. Grinding is often the most cost-effective option for a wide range of applications.

The grinding process involves a rotating grinding wheel that removes material from the workpiece, resulting in a very fine surface finish and tight tolerances.

Advantages of Grinding

Precision and Accuracy:

Grinding can achieve extremely tight tolerances, often within microns, making it ideal for high-precision components.

Surface Finish:

The process produces an excellent surface finish, which is often necessary for parts that need to minimize friction or wear.

Material Hardness:

Grinding is suitable for hard materials, including hardened steels and ceramics, which are difficult to machine with other processes.

Consistency:

The process has a high degree of consistency and repeatability, which is critical for high-volume production.

Disadvantages of Grinding

Cost:

Grinding can be more expensive than other machining processes due to the cost of the grinding wheel and the need for specialized equipment.

Time Consuming:

The process is generally slower than turning, which can be a disadvantage for high-volume production.

Complex Setup:

Grinding machines often require complex setups and skilled operators, which can increase initial setup time and labor costs.

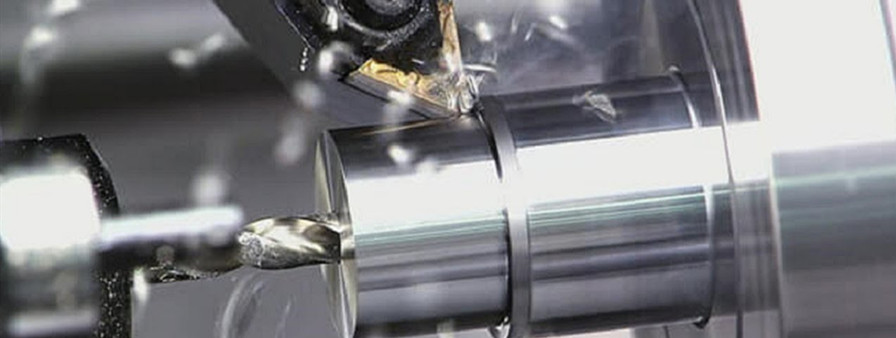

Hard Turning Overview

Hard turning is an effective alternative to grinding that is specifically designed for machining workpieces with a hardness of over 45 HRC using single-point cutting tools, especially for medium to high volume production. This advanced process is distinguished from standard turning by its ability to process extremely hard materials, blending the precision of grinding with the flexibility of turning operations. It is particularly good at achieving finishes and tolerances comparable to grinding, but with much greater efficiency. Hard turning not only simplifies the machining process of hard materials, but also offers significant advantages in speed, cost-effectiveness and flexibility, making it an increasingly popular choice in modern manufacturing environments where time and resource efficiency are critical.

Advantages of Hard Turning Over Grinding

Hard turning has several distinct advantages over grinding, making it an attractive option in a variety of manufacturing scenarios:

Reduced Setup Time:

Hard turning setups are generally simpler and faster than grinding. This efficiency stems from the fact that hard turning can be performed using a standard CNC lathe, eliminating the need for the complex setup and calibration often required in grinding operations. This advantage is particularly important in situations where fast turnarounds or frequent production changes are required.

Flexibility for small batch production:

Hard turning is more cost-effective for small batch production. This is because shorter setup times and lower tooling costs make it more economical when producing smaller quantities of parts. Unlike grinding, which requires specialized equipment and setup, and is more time-consuming and costly for small batch production, hard turning can be quickly adapted to different production needs.

Reduced Environmental Impact:

Hard turning is considered more environmentally friendly compared to grinding. This is because fewer consumables are used in hard turning, such as cutting tools, which generally last longer and produce less waste than the grinding wheels and coolants used in grinding. In addition, hard turning generally has lower energy consumption, which further increases its environmental benefits.

Streamlined Production Process:

Hard turning can be seamlessly integrated with other machining processes, streamlining the entire production process. This integration reduces the need to transfer parts between different machines for separate operations, streamlining the production process and reducing processing time. The ability to complete multiple machining processes on a single machine not only saves time, but also reduces the possibility of errors that can occur during part transfer.

Limitations of Hard Turning Compared to Grinding

While hard turning has many advantages, it also has certain limitations compared to grinding, especially in the following areas:

Material Suitability:

Hard turning is less effective for extremely hard or brittle materials. Such materials can cause rapid tool wear or damage during turning, so grinding is a better choice for such materials.

Surface Finish:

Grinding is often preferred for ultra-fine surface finishes. While hard turning offers high precision, it may not achieve the same smoothness as grinding, especially for applications that require a mirror finish.

Part Shape and Size:

Hard turning is primarily suited for parts with rotated geometries and may have difficulty processing very small or complex parts. Grinding, on the other hand, can process a wider range of shapes and sizes, including complex and irregular geometries.

Extreme Precision Requirements:

When extremely tight dimensional tolerances are required, grinding can provide greater precision compared to hard turning. This is especially important in industries where micron-level differences are critical.

What is the difference between hard turning and soft turning?

Hard turning is specifically used to machine hardened materials (HRC 45 and above), using strong tools such as CBN or ceramics to achieve efficient and precise surface finishes without the need for secondary grinding. In contrast, soft turning is more suitable for machining softer materials such as aluminum, mild steel, brass and plastics. The cutting tools used in soft turning are usually made of carbide or high-speed steel (HSS), which are well suited to the lower cutting forces and temperatures encountered when machining these materials. Soft turning is characterized by faster cutting speeds and the ability to achieve fine surface finishes, making it ideal for applications that require smooth surfaces and dimensional accuracy. Unlike hard turning, which focuses on high precision and difficult materials, soft turning emphasizes efficiency and the best performance of softer materials, without the need for tools specifically designed for hardness and heat resistance.

How To Choose Between Them

There are several key factors to consider when choosing between grinding and hard turning to ensure optimal performance, cost-effectiveness, and quality.

Material Hardness

Hard turning is typically used for materials with a hardness of more than 45 HRC, such as hardened steel and certain alloys. Cutting tools, typically made of cubic boron nitride (CBN) or ceramics, can effectively handle these hard materials. However, extremely hard or brittle materials are a challenge for hard turning because they can cause excessive tool wear or failure.

In contrast, grinding is better suited for extremely hard or brittle materials, such as ceramics, hardened steel above a certain hardness level, and glass. The abrasive action of grinding can cut these materials with high precision without damaging the workpiece. In addition, compared to hard turning tools, grinding wheels are more resistant to wear when machining very hard substances.

Tolerances and Finish

Grinding stands out when it comes to achieving ultra-tight tolerances and excellent surface finish. It can achieve tolerances within a few microns, making it ideal for high-precision components. The process also produces an exceptionally smooth surface, which is critical for applications that require low friction, high wear resistance, or aesthetic qualities.

While hard turning is capable of achieving good tolerances, it generally cannot achieve the precision of grinding. The surface finish is typically rougher, but is usually adequate for many industrial applications. If post-processing steps such as polishing can be performed, hard turning can still meet the required finish standards.

Output

For high-volume production, grinding offers excellent consistency and repeatability. This gives it an advantage in high-volume production, where maintaining part consistency is critical. Additionally, grinding is more easily automated, further enhancing its suitability for mass production.

However, hard turning is more economical for small batches, as setup time and costs are lower. The flexibility of CNC lathes used in hard turning allows for rapid reprogramming of different parts, allowing the process to be adapted to different production needs. This flexibility is particularly beneficial for manufacturers who need to frequently switch between different components.

Cost

Hard turning generally involves lower initial setup costs, as it can be performed on a standard CNC lathe, without the need for specialized equipment. While cutting tools are expensive, these costs are offset by the lower setup costs and versatility of CNC lathes. Hard turning also tends to have shorter cycle times, which reduces labor and operating costs for small to medium-volume production.

Grinding, on the other hand, often requires a higher initial investment due to the cost of the grinding machine and equipment. Grinding wheels can sometimes be expensive, but can last a long time when used properly. For large-volume production, the lower unit cost due to high consistency and reduced need for rework can offset the higher initial setup cost.

Complexity of Features

Hard turning offers greater flexibility for machining parts with complex geometries or multiple features in a single setup. This includes threading, contouring, and slotting, which can be performed sequentially without changing machines. The multi-axis capabilities of CNC lathes used in hard turning allow for intricate and detailed machining of parts with complex shapes.

Grinding, while less flexible in creating complex geometries with a single setup, excels in producing certain specialty features. Grinding is unmatched when it comes to tasks such as precise grooves, ultra-fine surface finishes, and maintaining precise dimensions. However, grinding may require separate processes or machines for different features, which can increase setup time and cost for parts with multiple complex features.

Conclusion

The choice between grinding and hard turning depends on a variety of project-specific factors. Grinding excels in precision and surface finish, making it an indispensable process for high-tolerance applications. On the other hand, hard turning offers cost savings, increased flexibility, and reduced cycle times, which are beneficial for many applications. Evaluating materials, tolerance requirements, production volumes, and cost considerations will help you determine the best machining process for your project.