The automotive industry is constantly evolving, with increasing demands for precision, efficiency, and scalability. One of the technologies that enable these demands is CNC turning. CNC turning is a highly versatile and efficient machining process that produces rotational, cylindrical, or conical parts with remarkable accuracy and repeatability. Through automated control of cutting tools and the workpiece, CNC turning helps manufacturers achieve tighter tolerances, faster production times, and consistent quality—qualities that are crucial for automotive components.

This article explores how CNC turning is applied in the automotive sector, highlighting its advantages, key applications, and the technologies that are driving its evolution.

What Is CNC Turning?

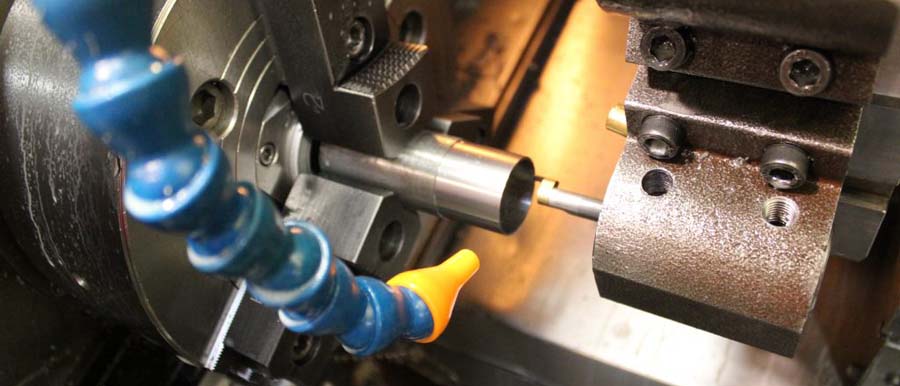

CNC turning is a subtractive manufacturing process in which a cutting tool removes material from a rotating workpiece. This is done with the help of CNC lathes or turning centers, where computer programs dictate the movements of the tool and the rotation speed of the workpiece. The process is ideal for creating symmetrical parts with high precision, such as shafts, bushings, and other cylindrical components.

CNC turning machines are equipped with multi-axis capabilities, enabling them to perform complex cuts and multi-dimensional shaping without the need for manual intervention. This automation not only increases production efficiency but also minimizes human error, making it an indispensable technology for the automotive industry.

Advantages of CNC Turning in Automotive Manufacturing

1. High Precision and Accuracy

CNC turning allows for extremely tight tolerances, often up to ±0.01 mm. This level of precision is essential for automotive components that must fit together seamlessly, such as engine parts, gear shafts, and transmission components.

2. Consistency and Repeatability

One of the greatest strengths of CNC turning is its ability to produce identical parts consistently over long production runs. This repeatability is crucial for maintaining quality standards in mass-produced automotive components.

3. Increased Production Speed

Modern CNC turning machines are capable of high-speed operations, reducing cycle times and accelerating manufacturing processes. Multi-axis turning centers can perform various operations simultaneously, such as turning, drilling, and threading, further optimizing production time.

4. Reduced Waste and Cost Efficiency

CNC turning is optimized for material usage, resulting in less waste during machining. This efficiency reduces material costs and contributes to a more sustainable manufacturing process.

5. Enhanced Safety and Automation

CNC turning minimizes human involvement, reducing the risk of accidents and improving workplace safety. Automated operations also allow machines to run continuously, even without human supervision, maximizing productivity.

Key Applications of CNC Turning in the Automotive Industry

1. Engine Components

CNC turning is used to produce high-precision engine parts such as pistons, crankshafts, camshafts, and cylinder heads. These components require exceptional accuracy and surface finish to function reliably under extreme conditions.

2. Transmission Parts

Precision-machined gears, shafts, and couplings are vital to the smooth operation of a vehicle’s transmission system. CNC turning ensures that these parts are manufactured with exact specifications to prevent malfunction and wear.

3. Suspension Systems

Key suspension components like shock absorber parts and strut mounts are manufactured using CNC turning. Accurate machining is necessary to maintain proper alignment and durability over time.

4. Brake System Components

Brake discs, hubs, and caliper mounts are critical for vehicle safety and performance. CNC turning produces these parts with the necessary strength and precision to endure high stress and wear.

5. Steering Mechanisms

CNC turning is used to craft high-tolerance parts for steering systems, including tie rods, ball joints, and steering shafts, ensuring reliability and safety.

6. Exhaust System Parts

Machining of flanges, muffler parts, and connector joints is commonly performed with CNC turning. These components must fit together with precision to maintain exhaust flow and emissions control.

Emerging Technologies Enhancing CNC Turning in Automotive Manufacturing

1. Multi-Axis Machining

Advanced multi-axis CNC turning centers allow for complex geometries to be machined in a single setup, reducing handling and improving accuracy. This is particularly useful for custom automotive parts and prototypes.

2. Digital Twin Technology

Digital twin technology enables real-time simulation of the machining process, allowing engineers to identify potential issues and optimize tool paths before actual production begins.

3. IoT Integration

Internet of Things (IoT) integration allows CNC turning machines to communicate with centralized monitoring systems, providing real-time data on machine health, tool wear, and production metrics.

4. Advanced Tooling Materials

Innovations in carbide and ceramic tooling extend tool life and improve cutting efficiency, enabling faster machining of hard metals like stainless steel and titanium.

Conclusion

CNC turning has established itself as a cornerstone technology in the automotive industry, supporting the production of high-precision, durable, and consistent components. As the demand for quality and efficiency continues to rise, advancements in CNC technology are pushing the boundaries of what is possible in automotive manufacturing. From engine parts to brake systems, CNC turning ensures that modern vehicles are built to perform reliably and safely.

By integrating IoT, multi-axis capabilities, and advanced digital simulations, CNC turning is poised to drive the next generation of automotive innovation—one precisely machined component at a time.