With the global emphasis on environmental protection and sustainable development, the electric vehicle industry is developing at an unprecedented speed. As the core force of modern manufacturing, CNC machining technology is providing strong support for the future of electric vehicles. This article will explore how CNC machining can help the development of the electric vehicle industry.

Meeting The Needs Of High-precision Parts For Electric Vehicles

The core components of electric vehicles, such as battery systems, motors and drive systems, have strict requirements on the accuracy of parts. Taking the battery shell as an example, CNC machining, with its excellent precision control capabilities, can ensure that the shell size is accurate and fits the battery module tightly, providing reliable physical protection for the battery, while ensuring the electrical isolation performance inside the battery, effectively improving the safety and stability of the battery.

In terms of motor manufacturing, the machining accuracy of key components such as motor rotors and stators directly affects the efficiency and performance of the motor. CNC machining can achieve micron-level accuracy, ensure the dynamic balance of the rotor and the accuracy of the stator winding slot, make the motor run more smoothly and efficiently, reduce energy loss, and extend the range of electric vehicles.

Improve The Production Efficiency Of Electric Vehicles

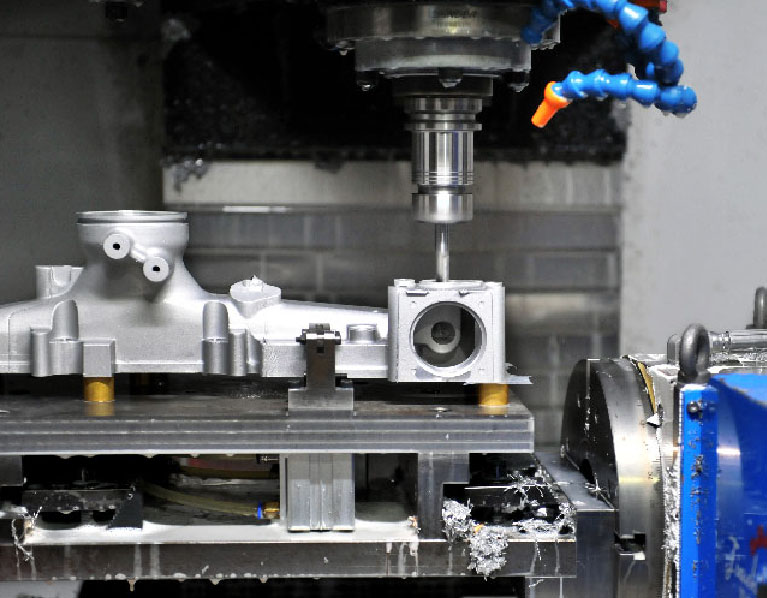

CNC machining equipment has highly automated and intelligent characteristics and can achieve 24/7 uninterrupted operation. In the large-scale production of electric vehicles, the automated processing process has greatly shortened the processing cycle of a single component and effectively improved the overall production efficiency. Through the preset processing program, CNC machine tools can quickly switch between different processing tasks, flexibly respond to the production needs of various components, reduce manual intervention, reduce human errors, and ensure the consistency and stability of product quality.

In addition, advanced CNC machining centers often have multi-axis linkage functions, which can complete the processing of multiple surfaces of complex components in one clamping, reducing the turnover time of workpieces between different processes, further improving production efficiency, and helping companies to quickly respond to the market’s strong demand for electric vehicles.

Assisting in the lightweight design and manufacturing of electric vehicle components

Lightweighting is an important means to improve the performance of electric vehicles and reduce energy consumption. CNC machining can perform high-precision processing on lightweight materials such as aluminum alloys and carbon fiber composites to achieve complex structural designs.

For example, in the manufacture of body frames and chassis components of electric vehicles, CNC machining is used to process aluminum alloy materials into high-strength, lightweight structural parts, which significantly reduces the weight of the body and reduces energy consumption during vehicle driving while ensuring the strength and safety of the body. For carbon fiber composite materials, CNC machining can accurately cut and shape, and produce parts with complex shapes, such as automotive interior parts, aerodynamic kits, etc., which not only achieves lightweight, but also improves the overall aesthetics and technological sense of the vehicle.

Supporting Innovative Design And Customized Production Of Electric Vehicles

With the increasing demand of consumers for personalized electric vehicles and the continuous pursuit of innovative design by automakers, the flexibility and programmability advantages of CNC machining are becoming more and more prominent. In the product development stage, engineers can use CNC machining to quickly make prototypes, quickly transform design concepts into physical models, and conduct performance testing and design optimization in a timely manner to shorten the product development cycle.

In the mass production stage, by modifying the CNC machining program, the machining parameters of the parts can be quickly adjusted to achieve customized production of electric vehicle parts of different styles and configurations to meet the diverse needs of the market. For example, some high-end electric vehicle brands provide customers with personalized interior customization services, and use CNC machining to create exclusive center consoles, seat adjustment buttons and other interior parts for customers, thereby improving product added value and user satisfaction.

Promoting The Sustainable Development Of The Electric Vehicle Industry

CNC machining can effectively reduce material waste while achieving high-precision and high-efficiency production. Through precise tool path planning and machining parameter optimization, CNC machine tools can maximize the use of raw materials, reduce cutting allowances, and reduce scrap rates.

In terms of energy consumption, advanced CNC machining equipment uses an intelligent energy consumption management system to adjust power output in real time according to machining tasks, reducing energy consumption per unit product.

In addition, CNC machining can realize the remanufacturing of waste electric vehicle parts, reprocessing recycled metals and other materials into usable parts, promoting resource recycling, and conforming to the concept of green and sustainable development of the electric vehicle industry.

Future Prospects Of CNC Machining And Electric Vehicles

Technological Innovation And Integration

In the future, CNC machining technology will be deeply integrated with emerging technologies such as 3D printing and artificial intelligence. For example, 3D printing can quickly form complex parts, while CNC machining is used for subsequent fine processing. This combination will greatly shorten the production cycle and reduce costs.

Intelligence And Automation

With the development of the industrial Internet, CNC machining equipment will be closely integrated with upstream and downstream production processes. Intelligent technologies such as online monitoring and predictive maintenance will significantly improve processing efficiency and product quality.

Market Demand growth

As the electric vehicle market continues to expand, the demand for high-precision and high-efficiency CNC equipment will continue to grow. CNC machining will play an important role in the manufacturing of more key components such as batteries, motors, chassis, etc. of electric vehicles

Conclusion

CNC machining technology, with its significant advantages in precision control, production efficiency improvement, lightweight manufacturing, innovation support and sustainable development, is deeply integrated into all aspects of electric vehicle production and manufacturing, laying a solid foundation for the performance improvement, cost control and market expansion of electric vehicles.

With the continuous advancement and innovation of technology, CNC machining will continue to push the electric vehicle industry to new heights, play a more critical role in the future green travel field, and help the electric vehicle industry achieve more brilliant development.